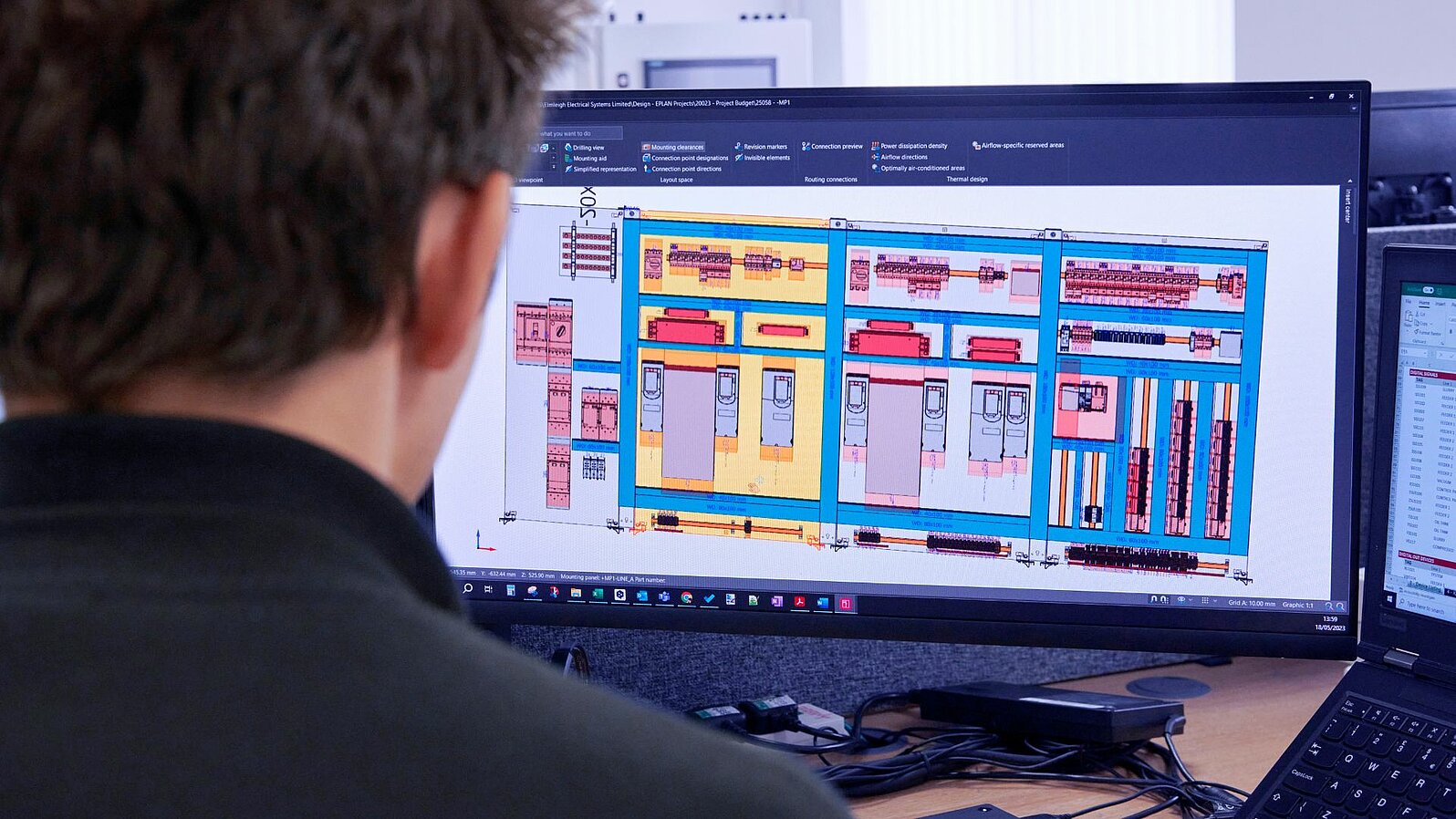

Unmatched Engineering Efforts

As a leading conveyor system integrator and general contractor, we deliver tailored solutions that meet exact customer specifications and adhere to rigorous industry standards. Our controls engineering and design services leverage advanced automation technologies, such as PLCs and SCADA systems, to ensure seamless operation and integration. Our mechanical engineering expertise focuses on designing robust conveyor components optimized for durability and performance. Through comprehensive commissioning and cycle time optimization, we enhance system efficiency and reliability, delivering turnkey solutions for diverse industrial applications.

- Conveyor System Integrator & General Contractor

- All Integrations per Customer Specs and Standards

- Controls Engineering & Design

- Mechanical Engineering & Design

- Commissioning

- Cycle Time Optimization