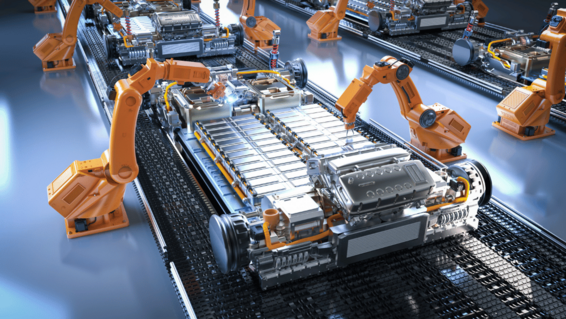

We aim to recruit the best workers and keep them with us long term. That’s why Leadec not only trains its new employees, but continuously offers professional development and opportunities to advance within the company. Technology in the e-mobility industry is constantly being improved, and we enable our team members to keep pace with the changes.

As an equal-opportunity employer, we also seek a diversity of backgrounds and experiences in our workforce to help us better understand the varied needs of our customers around the globe.

Leadec has received numerous awards from its industry partners for being a top-ranked employer. From 2018–2020, for example, a leading career platform in China awarded Leadec as the “China Best Employer” in the Industrial Services category, based upon a survey of 6,000 employees in 180 companies across Asia.