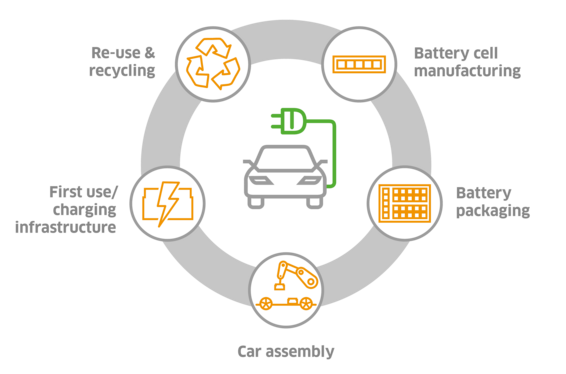

The battery is an electric vehicle’s central component. It accounts for 30 to 40 percent of the added value, and the cells in turn account for 60 to 80 percent of this. With its technical services and planning expertise, Leadec is the ideal partner for the cell factory. In China, for example, we provide technical facility management services in the factory of one of the top three battery cell producers in the world.

Battery production is a new territory for many OEMs. Leadec has been gaining experience in this field for years and has proven its competence. For a German premium brand, we have planned and set up the automation and screwdriving systems in the high-voltage battery assembly. Because complex assembly processes are the core element in the modern production of battery components or even entire systems. Batteries are very sensitive to shocks. Both during assembly and handling, care must be taken to ensure a "low-shock" process. A German OEM has entrusted us with the planning and project management of the assembly and testing facilities of its battery system for the internal lead unit for the USA and China. For our customers, the intelligence of the battery is contained in a highly complex overall system. Automated assembly systems and facilities for leak testing of assembled batteries are new fields of competence at Leadec.